GEA Westfalia Separator Group GmbH

Booth number: 5104

About us

GEA is one of the world’s largest systems suppliers for the food, beverage and pharmaceutical sectors. Our portfolio includes machinery and plants as well as advanced process technology, components and comprehensive services. Used across diverse industries, they enhance the sustainability and efficiency of production processes globally. The company supports customers across the entire value chain, from upstream oil & gas production to midstream transport and downstream refining. GEA's portfolio includes highly efficient separation, heat exchange, and refrigeration technologies designed to increase process reliability, reduce energy consumption, and meet stringent environmental regulations. Backed by decades of engineering expertise and global service capabilities, GEA is a trusted partner for optimizing processes and securing long-term profitability in the oil & gas industry.

In the Oil and Gas market, our centrifuges clean all kinds of liquids — from crude oil to meet refineries’ specifications to drain, bilge and produced water to help protect the maritime ecosystem. For the Energy market, our centrifuges provide reliable and efficient fuel and lube oil treatment solutions to ensure the safe and continuous high performance of diesel engines and gas turbines operating on a variety of different fuels.

Address

Werner-Habig-Str. 1

59302 Oelde

Germany

202 Kallang Bahru

#06-01

339339 Singapore

Singapore

E-mail: WSSingapore@gea.com

Phone: +65 63388113

Internet: www.gea.com

Contact person:

Regional Sales Manager, Oil & Gas Delvin Gho

E-mail: delvin.gho@gea.com

Phone: +65 9168 0647

Products & Services

Solution Offerings for Oil & Gas (for both Offshore and Onshore)

Drilling Mud Treatment and Barite Recovery

Crude Oil, Heavy Crude Oil, Bitumen dewatering and desalting

Water Treatment (Produced Water)

Water Treatment (Drain Water, Slop Water)

Slop Oil Treatment (MARPOL Oil Recovery)

MEG Treatment

Engine Protection (Liquid Fuels and Effluent treatment for gas turbine power plants)

Fuel / Crude / Hydraulic Oil / Lubrication Oil Treatment for Diesel & Turbine Engines

Equipment Offerings

Centrifugal Separators

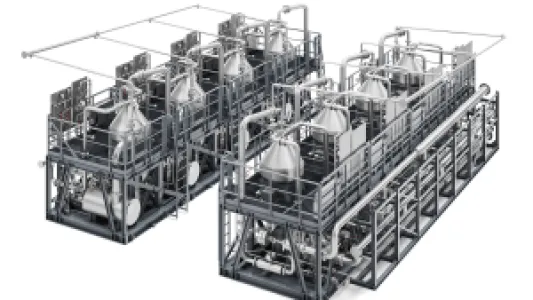

GEA separators are designed for liquid-based applications. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. They are equally as effective at separating liquid mixtures at the same time as removing solids.

Decanter Centrifuges

The decanter’s hour has come as soon as the solids content in the suspension to be processed is particularly high. These machines provide the benefits of high clarifying efficiency and maximum dewatering as well as the separation of liquids with the simultaneous removal of solids. The main requirements in this respect include a high bowl speed, a powerful drive for the scroll and a scroll speed which automatically adapts to the solids loading in the feed.

Centrifugal Separators

GEA separators are designed for liquid-based applications. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. They are equally as effective at separating liquid mixtures at the same time as removing solids.

Decanter Centrifuges

The decanter’s hour has come as soon as the solids content in the suspension to be processed is particularly high. These machines provide the benefits of high clarifying efficiency and maximum dewatering as well as the separation of liquids with the simultaneous removal of solids. The main requirements in this respect include a high bowl speed, a powerful drive for the scroll and a scroll speed which automatically adapts to the solids loading in the feed.

Produced Water Treatment

Considerable quantities of reservoir water are obtained as a by-product of oil and gas production processes. To protect both the environment and the reservoir formation, this water must be thoroughly processed. Untreated water cannot be returned directly into the sea, nor can it be used for re-injection to boost reservoir pressure. The objective is to ensure that no hazardous traces of oil or suspended solids enter the environment or the formation.

GEA supports this critical process with state-of-the-art, reliable, cost-effective, and high-performance centrifugal technology designed for use on drilling vessels, onshore facilities or on platforms.

Crude Oil Treatment

The innovative and robust GEA Crude Oil Treatment System meets the stringent requirements of the oil industry in relation to both product quality and environment. It can process crude oils with high densities and high water/salt content efficiently while minimizing the consumption of chemicals, which leads to considerable savings in operating costs.

Fuel Oil

During transport and storage, fuel oils used in the oil field industry are often contaminated with impurities that can damage sensitive engine parts. GEA treatment plants are globally used on FPSOs and drilling platforms to ensure reliable operation under extreme conditions.